Introduction

Do you ever wonder if the popularity PCB x-ray machines are attracting could be a key factor in its price determination?

PCB x-ray machines are rapidly gaining traction due to the need for electronics manufacturers to ensure their PCBs and installed components come out without defects. What’s more, is that advancements in electronics manufacturing and continuous improvements in electronic components keep getting PCB components tinier making the inspection work even more tedious.

read more : globepredict

However, this guide will make it easier for you to both be aware of the ranges of PCB X-ray costs and how you can save money by considering the most important factors specific to your PCB inspection.

So, if you are ready for the ride then hop in

I. What is PCB x-ray inspection?

To begin with, before any equipment or product can be certified suitable for use, it needs to be tested and that same test applies to Print Circuit Boards (PCBs) manufacturing. These tests ascertain its safe usage as this usage cuts across various sectors, and this is where PCB x-ray inspection comes in.

read more : topworldzone

PCB X-ray inspections are excellent ways of identifying hidden defects in PCBs as they use radiation to penetrate hard-to-reach components which are often difficult for visual inspections to identify.

The accuracy of the PCB X-ray machine is the real reason why these inspection tools are gaining major traction and popularity in the electronic manufacturing industry. More importantly, these inspections are necessary especially with recent Surface Mount Technologies (SMT) that allows components to become smaller and very compact and this could result in PCB components concealed between sheets.

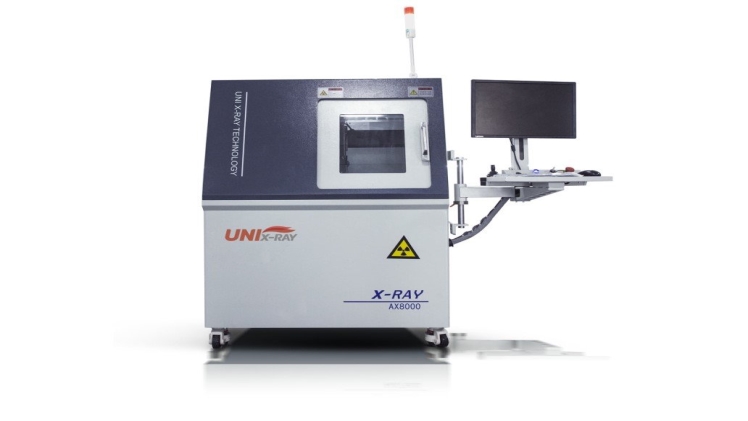

PCB X-ray machines comprise three major features which include the X-ray tube for generating X-ray photons. There is also the platform which is an operating mechanism that moves the material in different directions allowing it to be thoroughly inspected at different angles. Finally, the detector captures the photons generated and transforms them into a readable image to be analyzed and interpreted by a qualified inspection technician.

visit here to know more information : topworld45

II. What is a BGA X-ray inspection??

The Ball Grid Array is a surface mount technique to arrange components on PCBs. These arrangements are in a grid pattern, hence the derivation of the name. However, because the soldering connections to the surface panels are at the bottom of the grid, the quality of this soldering is to be confirmed, therefore the need for proper quality control.

Ball Grid Array X-ray inspection is a process that checks the connection between both chip and PCB for analysis to ascertain quality. This is also because the soldering connections become almost invisible to the natural onlooker.

The major reason why the Ball Grid Array inspection is highly challenging is the location of its connections, but other reasons also exist and this includes challenges in soldering, material reuse, quality control, undependable electrical tests, and cutting costs.

Visit here : onlinewebworld24

Inspection technicians must cultivate the use of accurate inspection measures using inspection tools like X-ray machines because of the importance of inspection as regards ball grid array technology. Also, ensuring BGAs are devoid of defects will reduce manufacturing costs associated with product recalls and mass callbacks.

III. How much does an x-ray machine cost?

Although different manufacturers and suppliers can have varying price lists as to the types and features of the X-ray machines they offer for sale. Nonetheless, many determinants must still be considered before purchasing PCB inspection equipment like X-ray machines. Here are a few ways you can save costs.

To save a few thousand bucks on your next purchase, you might want to watch out for promotional or discounted price offers. The reason is manufacturers tend to run promotional offers at certain times of the year especially during holiday periods. This can affect the cost of purchasing an X-ray machine.

Furthermore, some manufacturers supply inspectional equipment with unnecessary features such as sophisticated computerized features which are not necessarily needed for some product’s quality assessment. Therefore, the major features required for inspection should be thoroughly considered as unnecessary features can unnecessarily hike the price.

Thirdly, a cost-to-benefit analysis should be undertaken, and this can only be done by the buyer’s market expertise and quality assurance skill. More importantly, listing out what you’re looking out for in any inspection tool and going for it is crucial so that you don’t get overpriced and exorbitant inspection equipment.

Google has also always been useful in searching out companies and suppliers of affordable equipment since you can tailor your search options towards your required information.

Conclusion

In conclusion, trying to purchase an affordable PCB inspection X-ray machine can be daunting but when appropriate applicable elements are deployed such as targeting promotions and identifying what you need in an inspection tool, then your search constraint is halved.

Also, the three main parts of a PCB x-ray inspection equipment which are the x-ray tube, platform, and detector are the most crucial parts you should consider critically when purchasing a PCB X-ray machine. These pieces are often the cost determinants for any X-ray machine you choose to purchase.

In the end, your choice will greatly impact your PCB quality assessment processes and your cost reduction goals, so a critical examination of the above-mentioned factors is very important.